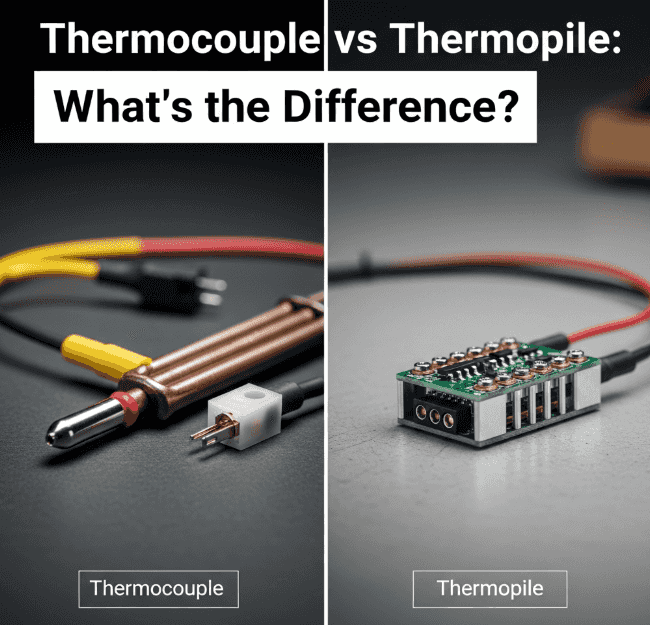

Thermocouple vs Thermopile: What’s the Difference?

Nov 07, 2025

In 2025, temperature sensing plays an increasingly critical role across many fields — from electric vehicles to industrial automation, from HVAC systems to consumer devices. Two sensor technologies keep showing up in design spreadsheets and engineering specs: thermocouples and thermopiles. Understanding their differences can save you time, money, and performance headaches.

Your company, Focusensing, pairs its sensor solutions with deep expertise in both types (and offers optimized products where fewer trade-offs are needed).

A thermocouple is one of the oldest and most used ways to sense temperature. At its simplest: two different metal wires are joined at one end (the “hot junction”), and the other ends form a reference (or “cold junction”). When the hot junction experiences a different temperature than the reference, a small voltage is generated (thanks to the Seebeck effect).

They are often capable of very high temperature measurement (some types go beyond 1000 °C).

They are robust, simple, and can be made compact.

Their output voltage is quite low (micro-volts to millivolts), which means the measurement system must handle small signals carefully.

They are typically “contact” sensors — the junction must touch or be embedded in the medium whose temperature is being measured.

A thermopile takes the thermocouple idea and amplifies it. Instead of a single junction pair, a thermopile uses many thermocouple junctions (often in series) so their voltages add up.

Because many junctions are combined, they generate a higher output voltage (compared to a single thermocouple).

Many thermopiles are designed for non-contact measurement (via infrared radiation) or small temperature differentials.

They tend to be more complex in packaging and design, because the junctions are arranged and must be thermally isolated and managed.

Here’s a side-by-side comparison to clarify when each technology makes sense:

| Feature | Thermocouple | Thermopile |

|---|---|---|

| Construction | One pair of dissimilar metals (junction) | Many thermocouple junctions in series/parallel |

| Output Voltage / Sensitivity | Low (µV-mV) per degree | Higher cumulative voltage output |

| Temperature Range | Very wide (including very high temps) | Generally used for moderate temps or non-contact gradients |

| Contact vs Non-Contact | Usually contact sensor | Often non-contact or radiation-based sensor |

| Complexity & Cost | Simple, lower cost | More complex, higher cost |

| Typical Applications | Furnace, engine exhaust, direct immersion | IR thermometers, thermal imaging, micro-temp sensing |

| Can you directly swap one for the other? | Not really — the measurement method and signal electronics differ. |

High-temperature industrial furnace or kiln where you need direct measurement at 1000 °C+

Engine exhaust sensors in automotive or aerospace environments where robustness is critical

When the sensor needs to survive harsh chemical, vibration, or high-temperature shock conditions

Non-contact or IR sensing (e.g., measuring surface temperature from a distance)

When you need higher output voltage for better signal-to-noise in low-signal environments

Applications where many small temperature changes are monitored (e.g., thermal cameras, energy harvesting)

When you’re designing a system or choosing sensor types, here’s a simple checklist:

What is the maximum temperature? If it’s extremely high (500 °C+), lean thermocouple.

Does the sensor need to contact the medium? If yes – thermocouple. If not – maybe a thermopile.

How important is signal strength or small ΔT detection? If you need high sensitivity and weak signals, thermopile may win.

What about cost and simplicity? If cost and simplicity matter a lot, thermocouple can be more economical.

Signal electronics and output voltage: Ensure the downstream electronics match the output levels. Thermopiles generate higher voltages but may need more careful calibration.

Environmental robustness: For extreme temperature, chemical exposure, vibration, direct immersion – thermocouples often have the edge.

At Focusensing, we understand that choosing the right sensor is only the first step — ensuring purchase, integration, and performance over time is what matters. With our deep sensor design pedigree and quality systems (including IATF 16949 and APQP practices), we support both thermocouple and thermopile options in our portfolio.

For thermocouples: We offer rugged probes, high-temperature sheaths, and calibration services.

For thermopiles: We deliver modules optimized for higher output, IR sensing or micro-temperature gradient detection.

From initial design consultation to volume production, Focusensing helps OEMs and system integrators avoid costly design mis-steps and post-launch failures.

If you’re looking to compare or select the right sensor type for your next system, our technical team can guide you — download our spec sheet or contact us for a design review today.

Higher integration: Thermocouples and thermopiles are increasingly paired with digital signal processors and smart calibration features.

Miniaturization: Smaller thermopile arrays, thinner thermocouple sheaths, flexible form factors for wearables and IoT.

Better materials & drift reduction: New alloys and fabrication techniques to reduce aging/drift in both types.

Energy harvesting: Thermopiles used not just for sensing but also for small-scale power generation (especially from waste heat).

Hybrid sensors: Systems may combine thermocouple and thermopile elements to exploit each’s strengths in one module.

Q: Can I swap a thermocouple in place of a thermopile?

A: No, not simply. A thermopile produces more voltage due to many junctions in series, and the downstream electronics expect those levels. Using a single thermocouple may lead to insufficient signal.

Q: Which is better for non-contact measurement?

A: Thermopile is generally better for non-contact IR sensing or where you measure temperature gradients rather than direct contact.

Q: Are thermopiles more expensive?

A: Typically yes, because of more complex construction and signal conditioning requirements.

Q: Can a thermocouple measure the same range as a thermopile?

A: Thermocouples often cover a wider range of extreme temperatures, but may lack the high sensitivity or non-contact capability of thermopiles.

Understanding the difference between thermocouple vs thermopile is crucial for getting your temperature sensing right — whether you’re designing an industrial control system, an EV battery pack, or a smart home device. Thermocouples bring robustness and wide range; thermopiles bring sensitivity and higher output voltage.

At Focusensing, we help you choose, design, and deploy the right sensor solution with confidence. Download our technical comparison guide or contact our sensor experts now to get started.